Stainless steel flange globe valve

Emcor Hass group Valves and Pipe Fittings:

valves in Kenya | Stainless steel flange globe valve | Copper Strainer | HDPE BUTT FUSION ADAPTOR | HDPE BUTT FUSION 90 DEGREE ELBOW in Kenya | CARBON STEEL BALL VALVE in Kenya | CARBON STEEL GATE VALVE | RUBBER JOINTS in Kenya | RUBBER JOINT KXT-A in Kenya | SWING CHECK VALVES in Kenya | CHECK VALVES in Kenya | WATER METERS in Kenya | Galvanized Iron (GI) Couplers in Kenya | Couplers in Kenya | Galvanized Iron Conduit Coupler in Kenya | Y STRAINER PN16 in Kenya | PEGLER Y STRAINER in Kenya | Galvanized Threaded Coupling in Kenya | BOLTS and NUTS in Kenya | BALL VALVES in Kenya | rubber gasket epdm in Kenya | End Caps in Kenya | HDPE Reducers in Kenya | globe valves in Kenya | Rubber seal check valves in Kenya | Gate valves in Kenya | single flange butterfly valves | PEGLER valves in Kenya | Valves and Pipe Fittings | check valves in Kenya | seal check valve in Kenya

Stainless steel flange globe valve

Product Advantages:

1. Precision casting valve body,

2 shot blasting treatment,smooth appearance, no trachoma.

2. CNC lathe processing of internal parts

3. Heavy type valve body.

4. Inverted seal treatment of contact surface between bonnet and stem to avoid leakage.

5. Each valve body is pickled and passivated to make the casting uniform and bright and improve corrosion resistance

6. Each valve will be inspected for shell and seal pressure before leaving factory.

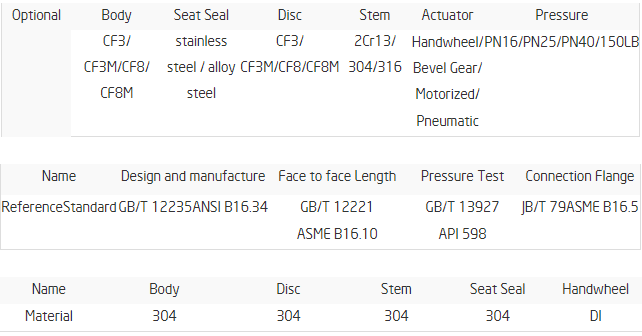

Parameters

- Overall rubber coating

Using high-quality rubber to overall coat the valve disc both inside and outside, with domestically leading rubber vulcanized technology, the valve is able to maintain accurate geometry size. What’s more, high adhesion between the rubber and valve disc makes the rubber steadily stick with good elastic memory.

- Corrosion resistance

The valve body is coated with epoxy resin powder, which can prevent the valve from corrosion and rusting, and the valve can be used in the wastewater system. Difficult to break, traditional gate valves are used to cause fracture because of the hit or collision from other objects. The new valve body material is ductile iron, which reduces the fracture situation remarkably.

- Three “O” ring seals

The stem with a three “O” ring seal design can reduce friction switch, significantly reducing water leakage. Besides, we can replace the valves without stopping the water construction.

- Helping to drink

Due to the internal body to non-toxic epoxy resin coating, the Inner and outer surfaces of the shutter is completely covered with rubber so it will not appear rust or corrosion, ensure water is available to drink.

- Body Casting

The body uses precision casting precise geometry, making it possible to ensure the valve seal without any other finishing to the inner of the valve.

- Lightweight

Body with a ductile cast made, lighter in weight than the conventional valve, about 20% to 30%, easy installation, and maintenance.

Emcor Hass group Valves and Pipe Fittings:

valves in Kenya | Stainless steel flange globe valve | Copper Strainer | HDPE BUTT FUSION ADAPTOR | HDPE BUTT FUSION 90 DEGREE ELBOW in Kenya | CARBON STEEL BALL VALVE in Kenya | CARBON STEEL GATE VALVE | RUBBER JOINTS in Kenya | RUBBER JOINT KXT-A in Kenya | SWING CHECK VALVES in Kenya | CHECK VALVES in Kenya | WATER METERS in Kenya | Galvanized Iron (GI) Couplers in Kenya | Couplers in Kenya | Galvanized Iron Conduit Coupler in Kenya | Y STRAINER PN16 in Kenya | PEGLER Y STRAINER in Kenya | Galvanized Threaded Coupling in Kenya | BOLTS and NUTS in Kenya | BALL VALVES in Kenya | rubber gasket epdm in Kenya |

End Caps in Kenya | HDPE Reducers in Kenya | globe valves in Kenya | Rubber seal check valves in Kenya | Gate valves in Kenya | single flange butterfly valves | PEGLER valves in Kenya | Valves and Pipe Fittings | check valves in Kenya | seal check valve in Kenya

Stainless steel flange globe valve

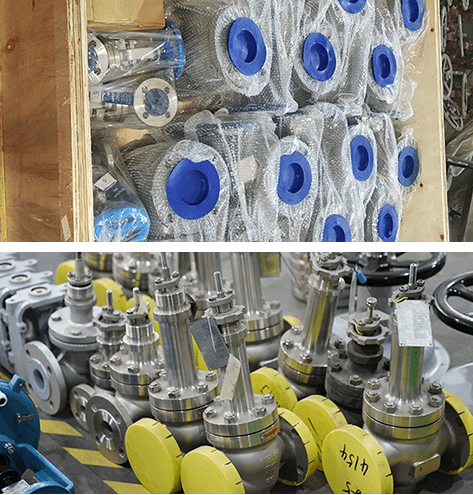

Project Name: Famous Textile Factory Project in Pakistan

Customer name: a boss in Pakistan

Main products: flow meters and SS valves

Customer needs: Textile mill applications

Project description:

This is a relatively special case.Because the customer know less about valves, but the demand is very large.So EMCOR assigns a professional team (salesmen and engineers from the International Trade Department) to conduct on-site inspections and give customer somePertinent suggestions,and this customer are very shocked and moved by our service, and have established a long-term cooperative relationship with us without hesitation;

client feedback:

The customer said: "Thank you very much for the on-the-spot inspection and very professional guidance of theEMCOR team." He was really shocked by the warm and considerate service and professional technical guidance ofEMCOR.EMCOR istrustworthy!

Project pictures:

Emcor Hass group Valves and Pipe Fittings:

valves in Kenya | Stainless steel flange globe valve | Copper Strainer | HDPE BUTT FUSION ADAPTOR | HDPE BUTT FUSION 90 DEGREE ELBOW in Kenya | CARBON STEEL BALL VALVE in Kenya | CARBON STEEL GATE VALVE | RUBBER JOINTS in Kenya | RUBBER JOINT KXT-A in Kenya | SWING CHECK VALVES in Kenya | CHECK VALVES in Kenya | WATER METERS in Kenya | Galvanized Iron (GI) Couplers in Kenya | Couplers in Kenya | Galvanized Iron Conduit Coupler in Kenya | Y STRAINER PN16 in Kenya | PEGLER Y STRAINER in Kenya | Galvanized Threaded Coupling in Kenya | BOLTS and NUTS in Kenya | BALL VALVES in Kenya | rubber gasket epdm in Kenya |

End Caps in Kenya | HDPE Reducers in Kenya | globe valves in Kenya | Rubber seal check valves in Kenya | Gate valves in Kenya | single flange butterfly valves | PEGLER valves in Kenya | Valves and Pipe Fittings | check valves in Kenya | seal check valve in Kenya

Stainless steel flange globe valve

Water treatment,

Petrochemical

Food and medicine

Electric energy

Metallurgy

Emcor Hass group Valves and Pipe Fittings:

valves in Kenya | Stainless steel flange globe valve | Copper Strainer | HDPE BUTT FUSION ADAPTOR | HDPE BUTT FUSION 90 DEGREE ELBOW in Kenya | CARBON STEEL BALL VALVE in Kenya | CARBON STEEL GATE VALVE | RUBBER JOINTS in Kenya | RUBBER JOINT KXT-A in Kenya | SWING CHECK VALVES in Kenya | CHECK VALVES in Kenya | WATER METERS in Kenya | Galvanized Iron (GI) Couplers in Kenya | Couplers in Kenya | Galvanized Iron Conduit Coupler in Kenya | Y STRAINER PN16 in Kenya | PEGLER Y STRAINER in Kenya | Galvanized Threaded Coupling in Kenya | BOLTS and NUTS in Kenya | BALL VALVES in Kenya | rubber gasket epdm in Kenya |

End Caps in Kenya | HDPE Reducers in Kenya | globe valves in Kenya | Rubber seal check valves in Kenya | Gate valves in Kenya | single flange butterfly valves | PEGLER valves in Kenya | Valves and Pipe Fittings | check valves in Kenya | seal check valve in Kenya

Please fill in your procurement needs and contact information

Emcor Hass group Valves and Pipe Fittings:

valves in Kenya | Stainless steel flange globe valve | Copper Strainer | HDPE BUTT FUSION ADAPTOR | HDPE BUTT FUSION 90 DEGREE ELBOW in Kenya | CARBON STEEL BALL VALVE in Kenya | CARBON STEEL GATE VALVE | RUBBER JOINTS in Kenya | RUBBER JOINT KXT-A in Kenya | SWING CHECK VALVES in Kenya | CHECK VALVES in Kenya | WATER METERS in Kenya | Galvanized Iron (GI) Couplers in Kenya | Couplers in Kenya | Galvanized Iron Conduit Coupler in Kenya | Y STRAINER PN16 in Kenya | PEGLER Y STRAINER in Kenya | Galvanized Threaded Coupling in Kenya | BOLTS and NUTS in Kenya | BALL VALVES in Kenya | rubber gasket epdm in Kenya |

End Caps in Kenya | HDPE Reducers in Kenya | globe valves in Kenya | Rubber seal check valves in Kenya | Gate valves in Kenya | single flange butterfly valves | PEGLER valves in Kenya | Valves and Pipe Fittings | check valves in Kenya | seal check valve in Kenya

There are no reviews yet.